- Bioprinting

- Melt Electrowriting

- Mechanobiology

- …

- Bioprinting

- Melt Electrowriting

- Mechanobiology

- Bioprinting

- Melt Electrowriting

- Mechanobiology

- …

- Bioprinting

- Melt Electrowriting

- Mechanobiology

Our Most Powerful Biofabrication

Platform, Yet.

Axo A3 is our most powerful bioprinting platform yet.

With its high mechanical precision and elevated system, Axo A3 is easy to use, plug and play bioprinting platform.

Melt Electrowriting: Available

Axo A3 enables researchers to use melt electrospinning writing on the same platform with a bioprinter.

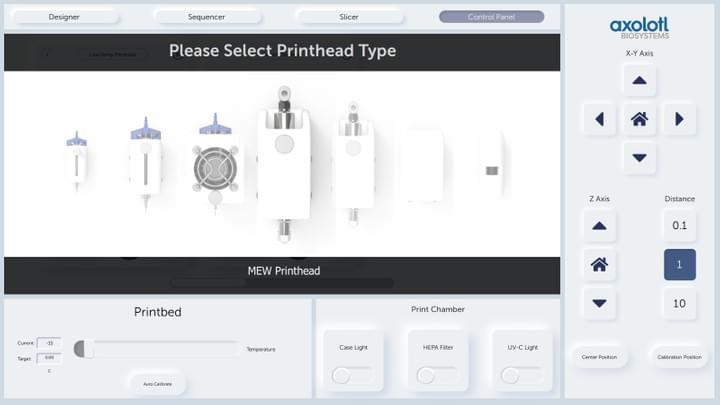

Printheads:

Variable Options

With different printhead options, Axo A3 becomes the tool of choice for your research. Heated Printhead, Cooled Printhead, Cell Electrowriting Printhead, Melt Electrowriting Printhead, UV Curing Toolhead, and HD Camera Toolhead can be integrated to meet your specific research needs.

Wide Pressure and

Temperature Range

Axo A3 has a wide pressure and temperature range to make sure your requirements are always met! We offer printhead solutions that can be heated up to 265°C and printbed that can be cooled down to -10°C thanks to a water-based cooling system. We also offer cooling systems to meet your needs. Axo A3 has a pressure range of 0 to 800 kPA.

UV-C Sterilization

With a UV-C Sterilization system, Axo A3 is safe from contamination. As a researcher-centered company, we know how delicate stem cells are. Our system uses UV-C to eliminate microbiological contamination. We also offer the necessary safety measures for you to use the platform outside of biological safety cabinets.

Technical Specifications

Bioprinting Technology

Pneumatic Driven Extrusion

Melt Electrowriting Technology

Available

Melt Electrowriting High Voltage Range

0kV - 15kV DC

Melt Electrowriting Current Range

0 µA - 150 µA

Melt Electrowriting Printing Velocity

<50 mm/s

Air Pressure Range

0 kPA - 800 kPA

XY Resolution Per Microstep

1 µm

Z Resolution Per Microstep

1 µm

Printhead Temperature Range

3°C - 265°C

Minimum Printbed Temperature

-10°C

Laser Based Photocuring System

50mW, 405 nm UV-Laser Module

LED Based Photocuring System

10W, 365/395/405/485/520 nm UV-LED Module

Layer Resolution

<10 µm

HD Camera Toolhead Image Resolution

Up to 1920*1080 pixels

Build Structure

Petri Dish, Well-Plate, PE Isolated Plate

Build Volume

130 x 90 x 100 mm

Printing Pressure Resolution

0.1 psi

Controling Software

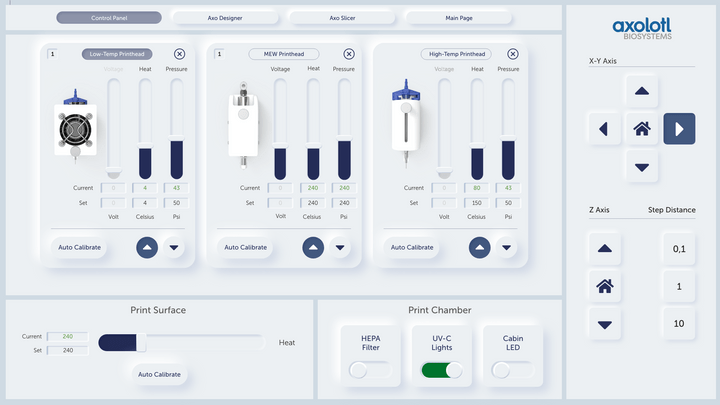

AxoSuite

Easy to Use Software

With the software specially developed for researchers, it is possible to configure printheads.

Modular Printhead System

With the software specially developed for researchers, it is possible to configure printheads.

We would love to give you more information about Axo A3 Bioprinting System.

We are ready to answer any questions you might have and always happy to receive feedback.

© Axolotl Biosystems Ltd. 2026, All Rights Reserved.